Publications

For an updated list of publications, please visit Google Scholar.

- Z. Smoqi, L. D. Sotelo, A. Gaikwad3, J.A. Turner, P. Rao, Nondestructive Ultrasound Evaluation of Additively Manufactured Wear Coatings, NDE&T International, Vol. 133, January 2023, 102754.doi:10.1016/j.ndteint.2022.102754

- S. Ramesh, C. Mahajan, S. Gerdes, A. Gaikwad, P. Rao, D.R. Cormier, I.V., Rivero,Numerical and Experimental Investigation of Aerosol Jet Printing, Additive Manufacturing, Volume 59, Part A, November 2022, 103090. doi:10.1016/j.addma.2022.103090, Collaboration with Rochester Institute of Technology (RIT).

- A. Riensche, J. Severson, R. Yavari, N. Piercy, K. Cole, P. Rao, Thermal Modeling of Directed Energy Deposition Additive Manufacturing using Graph Theory, Rapid Prototyping Journal (In-Press), July 2022. doi: 10.1108/RPJ-07-2021-0184

- H. Kobir, B. Bevans, R. Yavari, L. Castro, A. Riensche3, K. Cole, P. Rao, Thermomechanical Modeling in Additive Manufacturing using Graph Theory – Prediction of Recoater Crash, Progress in Additive Manufacturing, July 2022. Special Issue on Design and Modelling in Additive Manufacturing doi:10.1007/s40964-022-00331-5

- A. Gaikwad3, R. J. Williams, H. de Winton, B. D. Bevans3, Z. Smoqi3, P. Rao, P. A. Hooper, Multi-Phenomena Data Fusion for Enhanced Process Monitoring in Laser Powder Bed Fusion, Materials and Design, Volume 221, September 2022, 110919. Special Issue: In-line metrology, design optimization and material development in AM. doi: 10.1016/j.matdes.2022.110919, Collaboration with Imperial College, London

- A. Gaikwad3, T. Chang, B. Giera, N. Watkins, S. Mukherjee, A. Pascall, D. Stobbe, P. Rao, In-process Monitoring of Droplet-on-Demand Liquid Metal Jetting Additive Manufacturing using Machine Learning, Journal of Intelligent Manufacturing, Vol. 33, pp. 2093-2117, June 2022. doi: 10.1007/s10845-022-01977-2, Collaboration with Lawrence Livermore National Laboratory.

- Z. Smoqi, A. Gaikwad, B. Bevans, M.H. Kobir, J. Craig, A-A. Haj, A. Peralta, P. Rao, Prediction of Porosity in Laser Powder Bed Fusion using Physics-informed Meltpool Signatures and Machine Learning, Journal of Materials Processing Technology, Volume 304, June 2022, pp. 117550. Invited Special Issue Article: Additive Manufacturing – Process Qualification, doi: 10.1016/j.jmatprotec.2022.117550, Collaboration with Stratonics, Inc., and Honeywell, Inc.

- Z. Smoqi, B. D. Bevans3, A. Gaikwad, J. Craig, A. Abu-Haj, B. Roeder, B. Macy, J. E. Shield, P. Rao, Closed-loop Control of Meltpool Temperature in Directed Energy Deposition Additive Manufacturing Using a Co-axial Two-wavelength Pyrometer, Materials and Design, Volume 215, March 2022, 110508s doi: 10.1016/j.matdes.2022.110508, Collaboration with Stratonics, Inc.

- A. Ramalho, T.G. Santos, B.D. Bevans, Z. Smoqi, P. Rao, J.P. Oliveira, Effect of contaminations on the acoustic emissions during wire and arc additive manufacturing of 316L stainless steel, Additive Manufacturing, Volume 51, 2022 doi: 1016/j.addma.2021.102585. Collaboration with NOVA University, Lisbon, Portugal.

- S. Ramesh, O. Harrysson, P. Rao, A. Tamayol, D. R. Cormier, Y. Zhang, I. V. Rivero, Extrusion bioprinting: Recent progress, challenges, and future opportunities, Bioprinting, Volume 21, 2021, doi: 1016/j.bprint.2020.e00116., Collaboration with North Carolina State, Rochester Institute of Technology, and Connecticut.

- S. Gerdes, S. Ramesh, Azadeh Mostafavi, A. Tamayol, I. V. Rivero, P. Rao, Extrusion-based 3D (Bio)Printed Tissue Engineering Scaffolds: Process–Structure–Quality Relationships, ACS Biomaterials, Science and Engineering, 2021, 7, 10, 4694–4717, doi: 10.1021/acsbiomaterials.1c00598, Collaboration with, Rochester Institute of Technology and University of Connecticut.

- K. D. Cole, A. Riensche, P. Rao, Discrete Green's functions and spectral graph theory for computationally efficient thermal modeling, International Journal of Heat and Mass Transfer, Volume 183, Part B, February 2022, 122112. doi: /10.1016/j.ijheatmasstransfer.2021.122112

- R. Yavari, A. Riensche, E. Tekerek, L. Jacquemetton, H. Halliday, M. Vandever, A. Tenequer, V. Perumal, A. Kontsos, Z. Smoqi3, K. Cole, P. Rao, Digitally twinned additive manufacturing: Detecting flaws in laser powder bed fusion by combining thermal simulations with in-situ meltpool sensor data, Materials & Design, Volume 211, 2021, 110167. Special Issue: In-line metrology, design optimization and material development in additive manufacturing, pp :109229, doi: 10.1016/j.matdes.2021.110167. Collaboration with Sigma Additive, Drexel University, & Navajo Technical University

- R. Yavari, Z. Smoqi, A. Riensche, B. Bevans, H. Kobir, H. Mendoza, H. Song, K. Cole, P. Rao, Part-Scale Thermal Simulation of Laser Powder Bed Fusion Using Graph Theory: Effect of Thermal History on Porosity, Microstructure Evolution, and Recoater Crash. Materials & Design, Volume 204, 2021, 109685, Special Issue: In-line metrology, design optimization and material development in additive manufacturing, pp :109229 doi: 10.1016/j.matdes.2021.109685. Collaboration with Edison Welding Institute

- R. Yavari, R. Williams, A. Riensche, P. A. Hooper, K. D. Cole, L. Jacquemetton, H. Halliday, P. Rao, Thermal Modeling in Metal Additive Manufacturing using Graph Theory – Application to Laser Powder Bed Fusion of a Large Volume Impeller. Additive Manufacturing, Volume 41, 2021, doi:10.1016/j.addma.2021.101956 Collaboration with Imperial College London, Sigma Labs, Inc, and Navaho Technical University.

- R. Salary, J. Lombardi, D. Weerawarne, P. Rao, and M. Poliks, A Computational Fluid Dynamics (CFD) Investigation of Pneumatic Atomization, Aerosol Transport and Deposition in Aerosol Jet Printing (AJP) Process. Journal of Micro- and Nanomanufacturing, Volume 9, Issue 1: 010903 (16 pages), doi: 10.1115/1.4049958 Collaboration with Binghamton University and Marshall University

- R. Chen, P. Rao, Y. Liu, E. Reutzel, H. Yang, Recurrence Network Analysis of Design-quality Interactions in Additive Manufacturing, Additive Manufacturing (In-press, January 2021) doi: 10.1016/j.addma.2021.101861. Collaboration with Penn State and NIST.

- Z. Smoqi, J. Toddy, H. Halliday, J. E. Shield, and P. Rao. Process-Microstructure-Property Relationship in the Directed Energy Deposition of Cobalt-Chromium Alloy Coatings, Materials and Design, Volume 197, January 2021. Special Issue: In-line metrology, design optimization and material development in additive manufacturing, pp :109229.doi: 10.1016/j.matdes.2020.109229

- H. Yang, P. Rao, T. Simpson, Y. Lu, P. Witherell, A. R. Nassar, E. Reutzel, and S. Kumara, Six-sigma Quality Management of Additive Manufacturing. Proceedings of the IEEE Volume: 109, Issue: 4, April 2021 doi: 10.1109/JPROC.2020.3034519. Collaboration with NIST and Penn State.

- A. C. Gaikwad, B. Giera, G.M. Guss, J-B Forien, M. J. Matthews, and P. Rao. Heterogeneous Sensing and Scientific Machine Learning for Quality Assurance in Laser Powder Bed Fusion – A Single-track Study. Additive Manufacturing (Accepted, In-Press, October 7th, 2020). doi:/10.1016/j.addma.2020.101659

- R. Yavari, R.J. Williams, K. Cole, P. Hooper, and P. Rao. Thermal Modeling in Metal Additive Manufacturing using Graph Theory: Experimental Validation with In-situ Infrared Thermography Data from Laser Powder Bed Fusion. ASME Transactions, Journal of Manufacturing Science and Engineering, 142(12): 121005, 2020, doi: 10.1115/1.4047619.

- J. Williams, P. Rao, A. Samal, M. Johnson. Paired Trial Classification: A Novel Deep Learning Technique for MVPA. Frontiers of Neuroscience, Volume 14, Issue 47, April 2020. doi: 10.3389/fnins.2020.00417

- R. Salary, J. Lombardi, D. Weerawarne, M. Poliks, and P. Rao. A Computational Fluid Dynamics (CFD) Investigation of Pneumatic Atomization, Aerosol Transport and Deposition in Aerosol Jet Printing (AJP) Process. Journal of Micro- and Nanomanufacturing (Accepted, In-Press, October 15th, 2020)

- R. Salary, J.P. Lombardi, D. L. Weerawane, M.S. Tootooni, P. Rao, M. Poliks. A Sparse Representation-based Classification (SRC) Approach for Near Real-time Functional Monitoring of Aerosol Jet-Printed Electronic Devices. ASME Transactions, Journal of Manufacturing Science and Engineering 142(8): 081007, 2020. doi:/10.1115/1.4047045

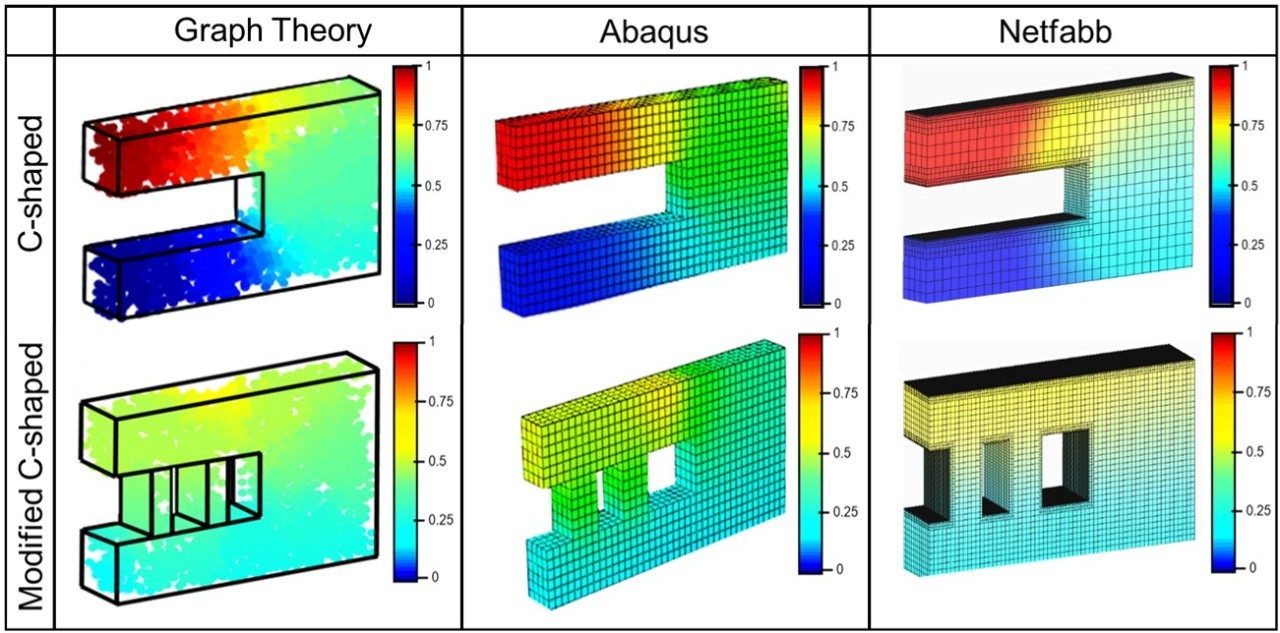

- K. Cole, R. Yavari, and P.Rao. Computational heat transfer with spectral graph theory: Quantitative verification, International Journal of Thermal Sciences. Volume 153, July 2020. doi: 10.1016/j.ijthermalsci.2020.10638

- S. Gerdes, A. Mostafavi, S. Ramesh, A. Memic, I. Rivero, P. Rao, and A. Tamayol. Process-Structure-Quality Relationships of 3D Printed PCL-Hydroxyapatite Scaffolds, Tissue Engineering (Part A), (Accepted, in-press, available online). doi: 10.1089/ten.TEA.2019.0237

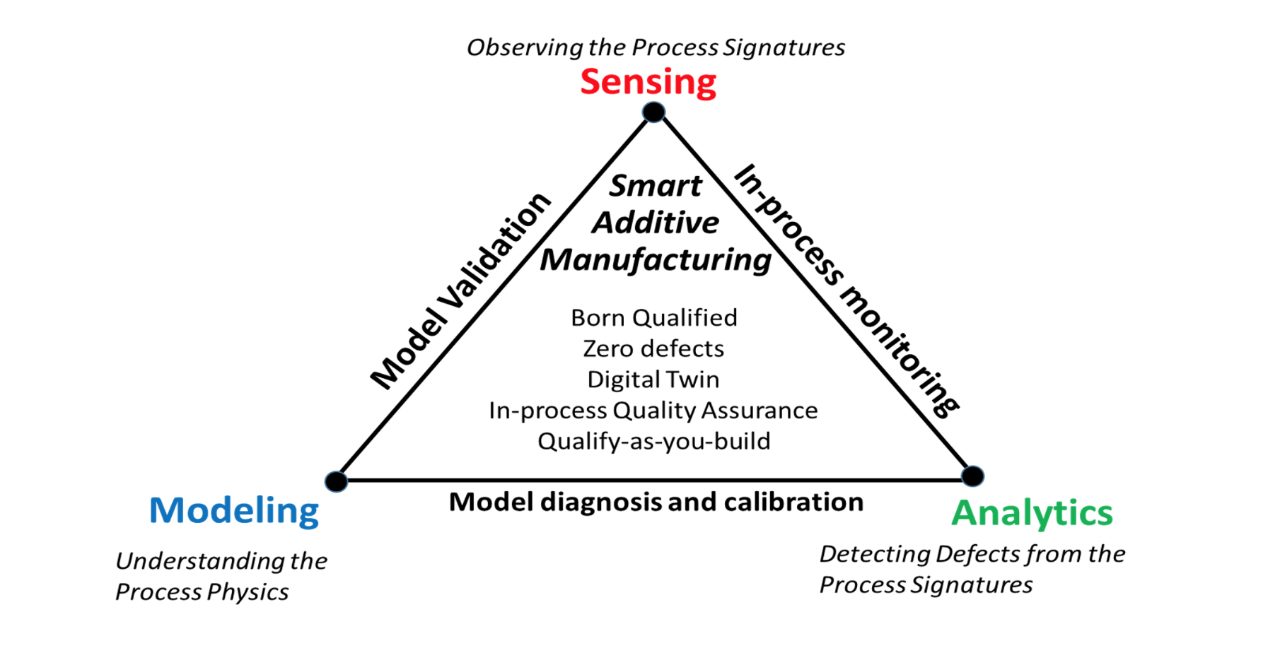

- A.C. Gaikwad, R. Yavari, M. Montazeri, K. Cole, L. Bian, P. Rao. Toward the Digital Twin in Metal Additive Manufacturing – Integrating Thermal Simulations, Sensing, and Analytics to Detect Process Faults, IISE Transactions (Accepted) doi: 10.1080/24725854.2019.1701753

- A.C. Gaikwad, F. Imani, H. Yang, E. Reutzel, and, P. Rao Prediction of Build Quality in Laser Powder Bed Fusion using Deep Learning of In-Situ Images, ASTM Journal of Smart and Sustainable Manufacturing System 3 (1), pp. 98-121, 2019. doi:10.1520/SSMS20190027

- M. Montazeri, A. Nassar. C. Stutzman, P. Rao Heterogeneous Sensor-based Condition Monitoring in Directed Energy Deposition, Additive Manufacturing, Volume 30, December 2019, 100916. doi.org/10.1016/j.addma.2019.100916.

- M. Amini, S.I. Chang, P. Rao. A Cybermanufacturing and Artificial Intelligence Framework for Laser Powder Bed Fusion (LPBF) Additive Manufacturing Process, Manufacturing Letters, 21, pp. 41-44, 2019. doi:10.1016/j.mfglet.2019.08.007

- M. Roy, R. Yavari, C. Zhou, O. Wodo, and P. Rao. Prediction and Experimental Validation of Part Thermal History in Fused Filament Fabrication Additive Manufacturing Process, ASME Transactions, Journal of Manufacturing Science and Engineering, 141(12), pp. 121001-10, 2019. doi: 10.1115/1.4045056

- M. Montazeri, A. Nassar, A. Dunbar, P. Rao, In-Process Monitoring of Porosity in Additive Manufacturing Using In-Process Optical Emission Spectroscopy Signals, IISE Transactions (Manufacturing and Design), 2019, Accepted, In-Press. doi: 0.1080/24725854.2019.1659525

- R. Yavari, K. Cole, P. Rao, Thermal Modeling in Metal Additive Manufacturing using Graph Theory. ASME Transactions, Journal of Manufacturing Science and Engineering, 2019, Vol. 141, pp. 0710071-20. doi: 10.1115/1.4043648

- J. Lombardi, R. Salary, D. Weerawarne, P.Rao, M. Poliks, Image-Based Closed-Loop Control of Aerosol Jet Printing Using Classical Control Methods, ASME Transactions, Journal of Manufacturing Science and Engineering, 141(7), 071011-20, 2019. doi: 10.1115/1.4043659

- L.J. Rhodes, M. Rios, J. Williams, G. Quiñones, P. Rao, V. Miskovic, The Role of Low-Level Image Features in The Affective Categorization Of Rapidly Presented Scenes, PLoS ONE 14(5): e0215975. doi: 10.1371/journal.pone.0215975

- F. Imani, B. Yao, R. Chen, P. Rao, H. Yang, Joint Multifractal and Lacunarity Analysis of Image Profiles for Manufacturing Quality Control (Technical Brief), ASME Transactions, Journal of Manufacturing Science and Engineering, 141(4), 044501-08, 2018. doi: 10.1115/1.4042579.

- J. Williams, P. Dryburgh, A. Clare, P. Rao, A. Samal, Defect Detection and Monitoring in Metal Additive Manufactured Parts through Deep Learning of Spatially Resolved Acoustic Spectroscopy Signals. ASTM Journal of Smart and Sustainable Manufacturing, Vol. 2(1), 204-226, 2018. doi/10.1520/SSMS20180035

- J. Liu, C. Liu, Y. Bai, Z. Kong, P. Rao, and C. Williams. Layer-wise Spatial Modeling of Porosity in Additive Manufacturing. IISE Transactions, (Additive Manufacturing Special Issue), Accepted, In-Press, 2018. Article Highlighted in January 2019 issue of the Industrial and Systems Engineer Magazine. doi:/10.1080/24725854.2018.1478169

- F. Imani, A. Gaikwad, M. Montazeri, P. Rao, H. Yang, E. Reutzel. Process Mapping and In-Process Monitoring of Porosity in Laser Powder Bed Fusion Using Layerwise Optical Imaging. ASME Transactions, Journal of Manufacturing Science and Engineering, 140(10), 101009-23, 2018. doi: 10.1115/1.4040615

- X. Wang, M. Sealy, R. Williams, P. Rao, Y. Guo. Stochastic Modeling and Analysis of Spindle Energy Consumption During Hard Milling. ASME Transactions, Journal of Manufacturing Science and Engineering, 140(6), 060801-14, 2018. doi: 10.1115/1.4038644

- M. Montazeri, P. Rao. Heterogeneous Sensor-based Build Condition Monitoring in Laser Powder Bed Fusion Additive Manufacturing Process using a Spectral Graph Theoretic Approach. ASME Transactions, Journal of Manufacturing Science and Engineering, 140(9), 091002-18, 2018. doi: 10.1115/1.4040264

- M. Montazeri, R. Yavari, P. Rao, P. Boulware. In-process Monitoring of Material Cross-Contamination Defects in Laser Powder Bed Fusion. ASME Transactions, Journal of Manufacturing Science and Engineering, 140(11), 111001-20, 2018. doi: 10.1115/1.4040543

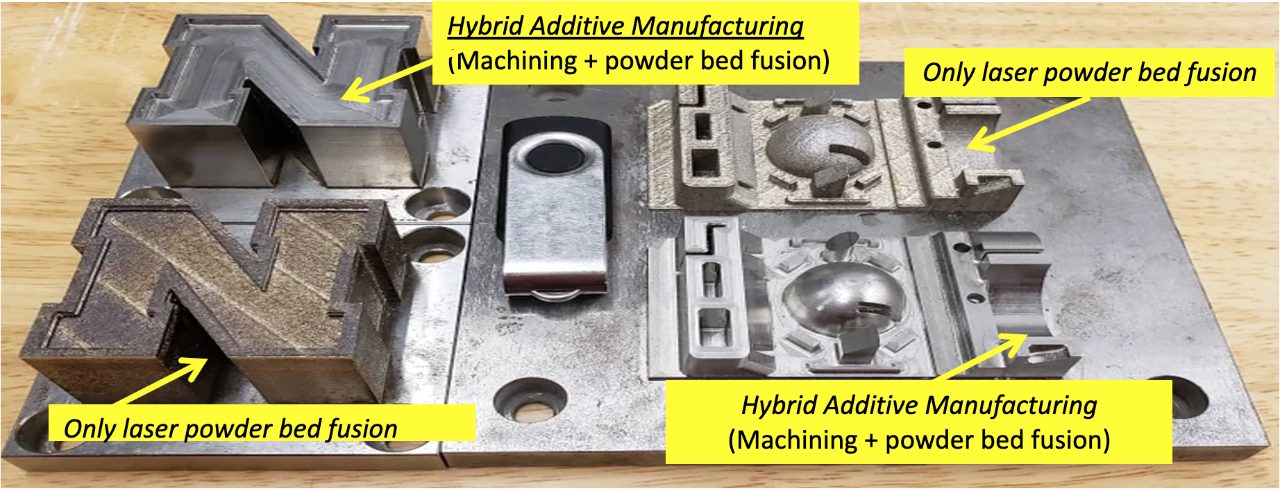

- M. Sealy, G. Madireddy, R. Williams, P. Rao, M. Toursangsaraki. Review Article - Hybrid Processes in Additive Manufacturing. ASME Transactions, Journal of Manufacturing Science and Engineering, Vol. 140(6), pp. 060801-14, 2018. doi:10.1115/1.4038644.

- H. Sun, P. Rao, Z. Kong, X. Deng and R. Jin. Functional Quantitative and Qualitative Models for Quality Modeling in a Fused Deposition Modeling Process. IEEE Transactions, Automation Science and Engineering, Vol. 15(1), pp. 393-403, 2018. doi: 10.1109/TASE.2017.2763609.

- M. S. Tootooni, P. Rao, C-A. Chou, Z. Kong. A Spectral Graph Theoretic Approach for Monitoring Multivariate Time Series Data from Complex Dynamical Processes. IEEE Transactions, Automation Science and Engineering, Vol.15(1), pp.127-144, 2018. doi: 10.1109/TASE.2016.2598094

- M. Khanzadeh, P. Rao, R. Jafari-Marandi, B. K. Smith, M. Tschopp, L. Bian. Characterizing the Geometric Accuracy of Additively Manufactured Components Using Self-Organizing Maps. ASME Transactions, Journal of Manufacturing Science and Engineering, Vol 140(3), pp. 031011- 031023, 2017. doi: 10.1115/1.4038598

- M. Aboutaleb, M. Tschopp, P. Rao, L. Bian. Accelerated Multiobjective Optimization of Part Geometric Accuracy in Additive Manufacturing (AM). ASME Transactions, Journal of Manufacturing Science and Engineering, Vol. 139(10), pp. 101001 – 101014, 2017. doi: 10.1115/1.4037319

- R. Salary, J. Lombardi, P. Rao, M. Poliks. Aerosol Jet Printing (AJP) of Flexible Electronic Devices: Online Monitoring of Functional Electrical Properties Using Shape-from-Shading (SfS) Image Analysis. ASME Transactions, Journal of Manufacturing Science and Engineering, Vol. 139(10), pp. 101010 – 101023, 2017. doi:10.1115/1.4036660

- M.S. Tootooni, A. Dsouza, R. Donovan, P. Rao, Z. Kong, P. Borgesen. Classifying the Dimensional Variation in Additive Manufactured Parts from Laser-Scanned 3D Point Cloud Data using Machine Learning Approaches. ASME Transactions, Journal of Manufacturing Science and Engineering, Vol. 139(9), pp. 091005 – 091019, 2017. doi: 10.1115/1.4036641

- M.S. Tootooni, C. Liu, D. Roberson, R. Donovan, P. Rao, Z. Kong, S.T.S. Bukkapatnam. Online Non-contact Surface Finish Machining using Graph-based Image Analysis. SME Journal of Manufacturing Systems, Vol. 41, pp. 266-276, October 2016. doi: 10.1016/j.jmsy.2016.09.007.

- R. Salary, J. Lombardi, M.S. Tootooni, R. Donovan, P. Rao, M. Poliks, P. Borgesen. Computational Fluid Dynamics Modeling and Online Monitoring of Aerosol Jet Printing Process. ASME Transactions, Journal of Manufacturing Science and Engineering, 139(2), pp. 021015-021036, October 2016. doi:10.1115/1.4034591

- J. Liu, Omer F. Beyca, P. Rao, Z. Kong, and S. Bukkapatnam. Dirichlet Process Gaussian Mixture (DPGM) Models for Real-Time Monitoring and its Application to Chemical Mechanical Planarization. IEEE Transactions, Automation Science and Engineering, Vol. 14(1), pp. 208-221, 2017. doi: 10.1109/TASE.2016.2599436.

- K. Bastani, P. Rao, and Z. Kong. An Online Sparse Estimation-based Classification (OSEC) Approach for Real-time Monitoring in Advanced Manufacturing Process from Heterogeneous Sensor Data. IIE Transactions, Quality and Reliability Engineering, 48(7), pp. 579-598, 2016. doi: 10.1080/0740817X.2015.1122254 Best Paper Award, Invited talk at IISE Conference, 2018. Article highlighted in the June 2016 (Volume 48, Number 9) Issue of the Industrial and Systems Engineer (ISE) Magazine.

- P. Rao, Z. Kong, C. Duty, R. Smith, V. Kunc, and L. Love. Assessment of Dimensional Integrity and Spatial Defect Localization in Additive Manufacturing (AM) using Spectral Graph Theory. ASME Transactions, Journal of Manufacturing Science and Engineering, 138(5), pp. 051007, 2015. doi: 10.1115/1.4031574

- O. Beyca, P. Rao, Z. Kong, S. Bukkapatnam, and R. Komanduri, Heterogeneous Sensor Data Fusion Approach for Real-time Monitoring in Ultraprecision Machining (UPM) process using non-parametric Bayesian clustering and evidence theory. IEEE Transactions, Automation Science and Engineering, 13(2), pp.1033-1044, 2016. doi: 10.1109/TASE.2015.2447454

- P. Rao, J. Liu, D. Roberson, and Z. Kong, and C. Williams. Online Real-time Quality Monitoring in Additive Manufacturing Processes using Heterogeneous Sensors. ASME Transactions, Journal of Manufacturing Science and Engineering. 137(6), pp. 061007, 2015. doi: 10.1115/1.4029823.

- P. Rao, S. Bukkapatnam, O. Beyca, Z. Kong, K. Case, and R. Komanduri. A Graph-Theoretic Approach for Quantification Of Surface Morphology and Its Application To Chemical Mechanical Planarization (CMP) Process. IIE Transactions, Quality and Reliability Engineering, 47(10), pp. 1-24, 2015. doi: 10.1080/0740817X.2014.1001927 Best Paper Award (Honorable Mention), Invited talk at IISE Conference, 2017. Article highlighted in the September 2015, (Volume 47, Number 6) issue of the Industrial Engineer Magazine (now called Industrial and Systems Engineer)

- P. Rao, S. Bukkapatnam, O. Beyca, Z. Kong, and R. Komanduri. Real-time Identification of Incipient Surface Morphology Variations in Ultraprecision Machining Process. ASME Transactions, Journal of Manufacturing Science and Engineering, 136(2), pp. 021008, 2014. doi: 10.1115/1.4026210

- P. Rao, M. Bhushan, S. Bukkapatnam, Z. Kong, S. Byalal O. Beyca, A. Fields, and R. Komanduri, Process-Machine Interaction (PMI) Modeling and Monitoring of Chemical Mechanical Planarization (CMP) Process Using Wireless Vibration Sensors. IEEE Transactions, Semiconductor Manufacturing, 27(1), pp. 1-15, 2014. doi: 10.1109/TSM.2013.2293095

- S. Bukkapatnam, P. Rao, W-C. Lih, N. Chandrashekeran, and R. Komanduri, Process Characterization and Statistical Analysis of oxide CMP on a Silicon Wafer, Applied Physics (A), 88(4) pp. 785-792, 2007. doi:10.1007/s00339-007-4082-x

- S. Bukkapatnam, P.Rao, and R. Komanduri. Experimental Dynamics Characterization and Monitoring of MRR in Oxide Chemical Mechanical Planarization (CMP) Process. International Journal of Machine Tools and Manufacture, 2008, 48(12-13), pp.1375-1386. doi:10.1016/j.ijmachtools.2008.05.006.

- Wen-Chen Lih, S. Bukkapatnam, P. Rao, N. Chandrasekharan, R. Komanduri. Adaptive Neuro-Fuzzy Inference System Modeling of MRR and WIWNU in CMP Process with Sparse Experimental Data. IEEE Transactions, Automation Science and Engineering, 5(1), pp. 71 -83, 2008. doi: 10.1109/TASE.2007.911683

- S. Bukapatnam, R. Komanduri, H. Yang, P. Rao, W.C. Lih, M. Malshe, L.M. Raff, B. Benjamin, and M. Rockley. Classification of Atrial Fibrillation Episodes from Sparse Electro-Cardiogram Data. Journal of Electrocardiology, 41(4), pp. 292-299, 2008. doi:10.1016/j.jelectrocard.2008.01.004

- J.M, Govardhan, S. Bukkapatnam, Y. Bhamare, P. Rao, and V. Rajamani. Statistical analysis and design of RFID systems for monitoring vehicle ingress/egress in warehouse environments. Internaional Journal of Radi46. doi: 10.1504/IJRFITA.2007.013140

.